Why this topic is important

The new Packaging and Packaging Waste Regulation (PPWR) introduces binding requirements for the recyclability of packaging in the EU from 2030. Article 6 of this regulation represents a substantial change for companies marketing packaging. For KIVO and its customers, this calls for a proactive approach in packaging design and material use to ensure future market access.

What does Article 6 of the PPWR prescribe?

From 1 January 2030 only packaging material classified as recyclable may be placed on the market. The requirements for this are:

- Packaging should be able to be collected, sorted and recycled effectively after use, without compromising other waste streams.

- The recycled material must be of a quality that can replace the use of primary material.

- From 2035, it is no longer enough for a package to be theoretically recyclable: it must actually be widely recycled in existing infrastructures.

Classification of recyclability (Grades A, B, C)

From 2030, a European classification system will be introduced for recyclability:

| Grade | Recyclability rate | Market placement allowed until |

|---|---|---|

| A | ≥ 95% | unlimited |

| B | ≥ 80% to < 95% | unlimited |

| C | ≥ 70% to < 80% | until the end of 2037 |

| < 70% | N/A | banned from 2030 |

| Packaging with a recyclability of less than 70% will no longer be allowed from 2030. Grade C will be phased out from 2038: from then on, all packaging must be at least Grade B.

The classification is provisionally based on the methodology of RecyClass, subject to changes by the European Commission.

Design for Recycling becomes mandatory

The PPWR requires manufacturers to design packaging according to the principles of Design for Recycling, including:

- Use of monomaterials rather than multimaterial combinations

- Exclusion of interfering elements such as certain barrier coatings, adhesives or inks

- Suitability for existing sorting and recycling systems

From 2029 compliance with these Design for Recycling guidelines becomes a legal requirement.

Role and responsibilities within Design for Recycling

When assessing recyclability under Article 6 of the PPWR, it is important to distinguish between KIVO's role as a producer of film, bags and sleeves and the role of the party actually filling and marketing the packaging.

What lies within KIVO's sphere of influence?

Table 4 of Annex II provides a preliminary list of 11 parameters that will play a role within the recyclability assessment.

As a supplier of the PE films and bags, KIVO can provide information for some of those parameters. These include:

- Additives in the film

- Material composition of the film itself (polymer type, monomaterial composition)

- Barriers and coatings used by KIVO

- Dyes and masterbatches

- Ink systems, lacquers and coding applied by KIVO

These parameters form an important part of the technical basis for the recyclability check and preliminary Grade A, B or C classification.

Which parameters lie with the client (or his client)?

In practice, KIVO films are almost always further processed and used to package a product. Think of adding a label, filling the packaging, or even combining/laminating it with other materials, such as paper. As a result, several determining Design for Recycling criteria lie with the filler or brand owner. These include:

- Laminates with other materials, such as kraft paper or other substrates. When a film is laminated by another party, the test of the D4R criteria lies with the party marketing the composite packaging.

- Labels and tags, including material type, format and adhesives used.

- Sleeves, closures and other small packaging components.

- Adhesives added after delivery by KIVO.

- Prints added after delivery by KIVO

- Product residues and ease of emptying. Especially with food, powders, soil, oils and fats, knowledge about product residues left behind and the ease of emptying the packaging is crucial for recyclability. This knowledge logically lies with the party marketing the packaged product.

- Ease of disassembly of the overall packaging unit (e.g. the ease with which, in the case of a laminate, the multiple materials can be taken apart).

Final responsibility for recyclability grade

Because KIVO packaging is rarely marketed as final packaging without further processing, addition and filling, the final responsibility for Design for Recycling criteria and final recycling performance grade lies in almost all cases with:

- our client, or

- our customer's customer who fills the packaging and markets it as final packaging.

KIVO provides the necessary technical input for the packaging material we supply and supports the interpretation of the Design for Recycling guidelines. However, a complete and correct recyclability check is only possible when all additional parameters of the final packaging are taken into account by the economic operator actually marketing the packaging.

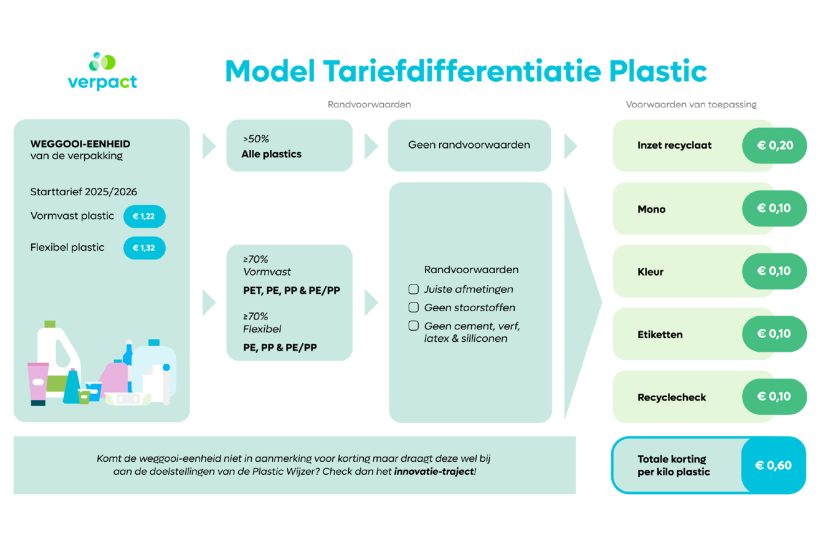

Financial incentives

From 2030, the level of packaging tax in EU member states (including the Netherlands) will be based on the recyclability grade. The better the recyclability, the lower the tax. This provides a direct financial advantage for packaging that meets higher recyclability standards.

What does this mean concretely for KIVO customers?

KIVO actively supports its customers in future-proofing packaging. Support includes the following activities:

- Redesign and optimisation towards Grade B or A, including through monomaterials or elimination of interfering elements.

- Support in compiling the mandatory packaging dossier, including rationale for lower tax rates based on the technical design.

Ready for a quick scan?

Curious about the current recyclability grade of your packaging or how to improve it to meet Grade B or A? Contact us for a no-obligation analysis or consultation on PPWR compliance.