European regulations around packaging are changing rapidly. With the introduction of the Packaging and Packaging Waste Regulation (PPWR), producers face stricter requirements on reuse, recyclability, recycled material use, packaging reduction and labelling. At the same time, practice shows that the availability of high-quality recyclate, especially polyolefins such as LDPE and LLDPE, lags behind.

Therefore, KIVO deliberately takes a dual approach: increasing the share of recyclate where possible and researching bio-based alternatives that fit within the long-term strategy.

Recyclate: first choice, but scarce

The use of post-consumer recyclate (PCR) is central to the PPWR. From 2030, all plastic packaging must achieve at least Grade C in terms of recyclability, and from 2038 even at least Grade B. In addition, the legislation sets clear targets for the proportion of PCR in plastic packaging:

- For flexible PE packaging:

- 10% PCR in contact-sensitive applications from 2030

- 35% PCR in non-contact-sensitive applications from 2030 onwards

Note: In applications with direct food contact, the use of PCR is not permitted, even in multilayer constructions with a virgin contact layer. In those cases, use of PIR or virgin PE is the preferred route.

Although KIVO through partners and its own recycling facility KIVO Recycling (PIR) invests heavily in availability, high-quality recyclates remain scarce. This is partly due to technical limitations in flexible materials and partly to stagnation in collection and sorting.

Costs and financial barriers: market reality

Besides technical constraints, economic considerations also play a major role. Clear price differences exist between virgin, mechanically recycled PCR, chemically recycled PCR and biobased materials:

- Virgin material is often significantly cheaper at the moment

- Mechanically recycled PCR is more expensive, partly due to limited availability

- Chemically recycled PCR is even more costly and only available to a limited extent

- Bio-based alternatives tend to be the most expensive option per kilogram

These higher costs make many packaging companies reluctant to adopt sustainable alternatives, especially in competitive markets.

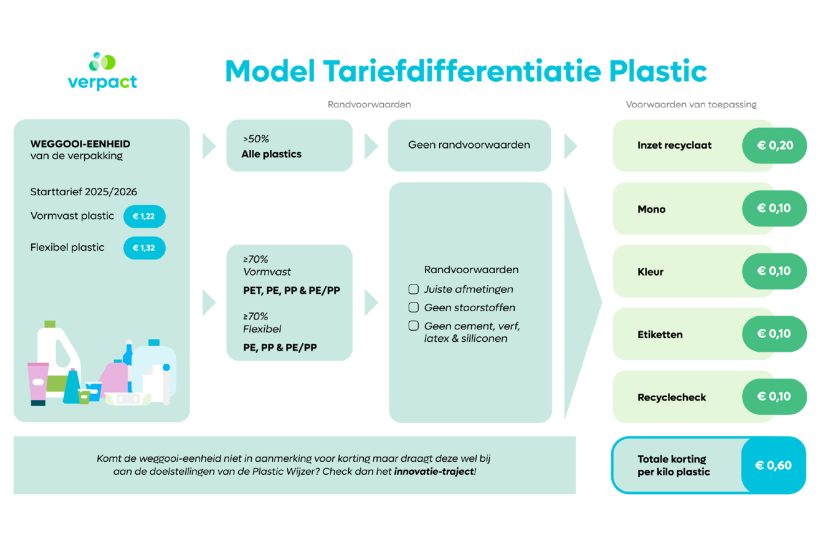

Financial incentives such as the packaging tax, in which well-recyclable or recyclate-produced packaging is tax favoured, can (partly) compensate for this. There are already concrete schemes for this in the Netherlands.

KIVO actively thinks about optimisation strategies that balance cost, tax burden and recyclability.

Bioplastics: alternative in development

To complement recyclate, the EU is actively exploring the role of bio-based plastics. A decision on the formal recognition of bio-based alternatives is expected around 2028 if PCR shortages persist or prove technically unsuitable. Within the flexible plastic packaging sector, this mainly involves bio-based PE.

Although PPWR recognises the potential, an EU-wide sustainability standard for biobased content is still under development. The environmental impact over the entire life cycle needs to be better substantiated before large-scale application is encouraged.

KIVO's approach: flexibility within the frameworks of circularity

For KIVO, it is essential to guide customers towards future-proof packaging solutions. That means:

- Commit to recyclate as primary route, subject to technical and legal approval

- Integrating biobased alternatives in niches where PCR is not (yet) applicable

- Design according to the strategy: Reduce → Recycle → Redesign → Renew.

What does this mean concretely for customers?

- For non-food applications, KIVO supports integrating certified PCR

- For food packaging without a direct contact layer, we recommend PIR or virgin PE, combined with Design for Recycling

- In structural absence of PCR or limited technical feasibility, bio-based materials may be an alternative

- We actively consider combinations of design and materials that lead to lower packaging loads

Conclusion: not an either-or, but an and-and

The combination of recyclate and bioplastics is not a contradiction for KIVO, but a necessary strategic flexibility. By investing in its own recycling facilities and cooperating with partners such as Circular Plastics Alliance, KIVO remains able to offer circular solutions with an eye for technical feasibility, legal frameworks and economic reality.