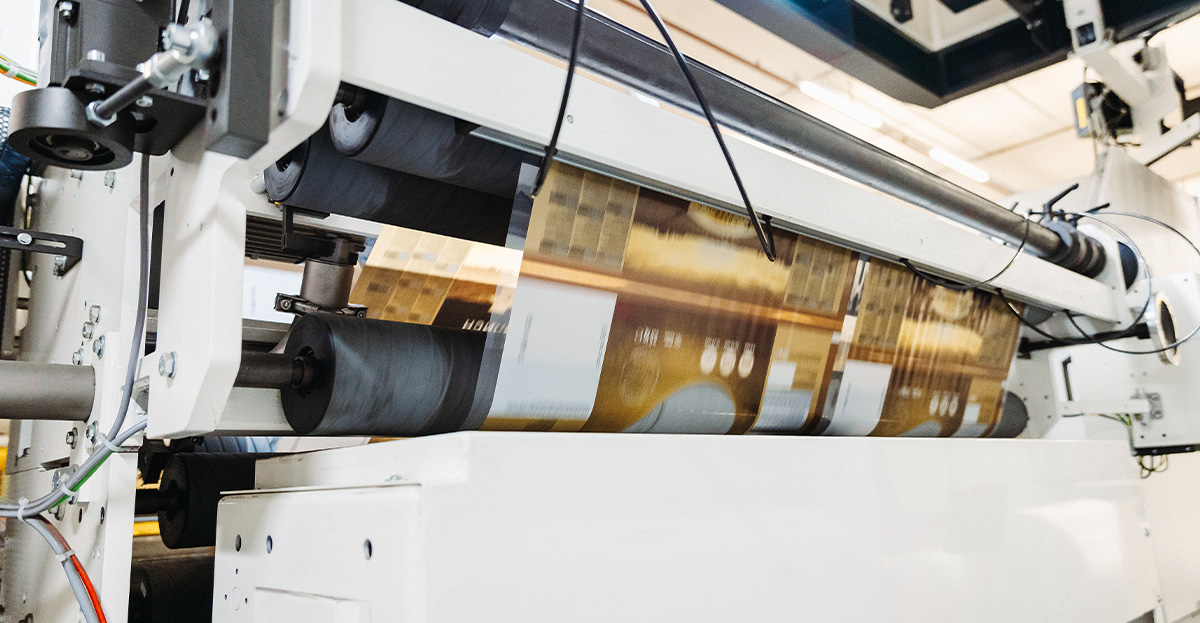

How flexo printing works

At KIVO, we are proud of our industry-leading flexo printing facility, equipped with state-of-the-art machinery capable of printing up to 10 colours. This process uses flexo techniques to deliver high-quality printing on all kinds of films. By proactively following and testing the latest developments, we remain at the top of the European flexo market. With our highly trained staff and award-winning quality, we ensure perfect colour consistency and environmentally friendly production.

Sustainable flexo printing

At KIVO, sustainability is at the heart of our flexo printing process. We minimise environmental impact by using fewer colours and reducing waste. Our afterburner neutralises alcohol vapours, so we comply with strict European laws and regulations. Innovative techniques allow us to achieve similar printing results with less ink, thus producing sustainable and environmentally friendly packaging.

Find out how our sustainable approach contributes to high-quality eco-friendly packaging solutions.

Our various flexo printing machines

At KIVO, we have an advanced machine park with several flexo printing machines, including a Miraflex (8 colours) and two Novoflex machines (8 and 10 colours). Both from the leading brand Windmöller & Hölscher. These machines are equipped with the latest technical gadgets, such as Kodak NX and GTT raster sleeve technology, and use highly pigmented inks from Doneck. Thanks to our high-quality colour management and viscosity control, we guarantee perfect colour quality and consistent printing results.